What Are Korean Nail Gels?

Korean nail gels have become a benchmark in modern nail technology, valued for their durability, rich pigmentation, and innovative finishes.

This section is designed to give both nail technicians and enthusiasts a clear understanding of what these products are, how they are formulated,

and the best practices for their safe and effective use. You will also find information on regulatory standards within the European Union,

ensuring that the knowledge provided here is not only practical but also compliant with the latest requirements.

All content is educational, fact-based, and brand-neutral to help you make informed decisions in your nail care and professional work.

Definition and Core Mechanism

Korean nail gels are UV/LED-curable coatings formulated to create a durable, glossy film on the nail plate. Unlike air-dry lacquers, these systems contain reactive monomers/oligomers and photoinitiators that polymerize (cross-link) into a solid resin when exposed to specific wavelengths of light.

For a clear primer on the curing chemistry, see this overview of gel polish chemistry.

Complete curing requires correct lamp output and exposure time; when done properly, the result is a coating that resists chipping and maintains gloss for two weeks or more under normal wear.

How Korean Gels Differ in Practice

“K-beauty” gel systems are typically soak-off, cosmetic-grade formulations with a higher proportion of gel resin and a lower proportion of volatile solvent.

In practice this yields a richer, self-levelling consistency and strong film integrity when the manufacturer’s curing instructions are followed.

Many Korean systems also emphasize “free-from” labelling (e.g., 5-free, 9-free, 10-free), omitting legacy solvents or plasticizers such as toluene, DBP, or formaldehyde releasers found in older product types.

A concise consumer-oriented explainer is available here:

What are Korean gels and why try them?.

Key Components and Polymerization

Typical constituents include (i) acrylate or methacrylate oligomers/monomers for film formation and adhesion; (ii) cross-linkers to increase hardness and solvent resistance; (iii) photoinitiators that absorb UV/LED energy and generate radicals to start polymerization; and (iv) pigments/effect particles for colour and visual effects. The polymer network that forms during curing governs properties such as gloss, flexibility, and abrasion resistance. Undercuring leaves residual monomer and can impair performance; over-thick layers may hinder light penetration and should be avoided.

Application and Curing Best Practices

- Prepare the nail plate by gentle cuticle work, removal of surface lipids, and light buffing; remove dust and dehydrate prior to base application.

- Apply thin, even layers (base, colour, top). Cap the free edge to reduce water ingress and edge lift.

- Use a lamp matched to the product class (wavelength/output). Cure each layer for the specified time; cure thumbs separately if needed to ensure direct exposure.

- Avoid uncured product on skin; clean margins before curing. Consistent avoidance of skin contact reduces sensitization risk.

Health and Safety Considerations

As with all acrylate-based UV systems, the principal risks arise from repeated skin exposure to uncured material and from undercured films.

Professional hygiene, appropriate gloves, and correct curing significantly reduce risk.

Users with a known acrylate allergy should consult a professional and consider low-sensitizer options and strict exposure control.

Do not peel cured coatings from the nail plate; use soak-off or file-off methods according to the manufacturer’s protocol to avoid nail damage.

Structured Manicures and Nail Health

Korean systems popularized “structured” gel techniques that use builder viscosities to create a controlled apex and balanced thickness.

When properly executed, these structures distribute mechanical stress, reduce edge lifting, and allow comfortable nail growth while keeping overall coatings thin.

For general consumer background on the approach, see

this introductory article.

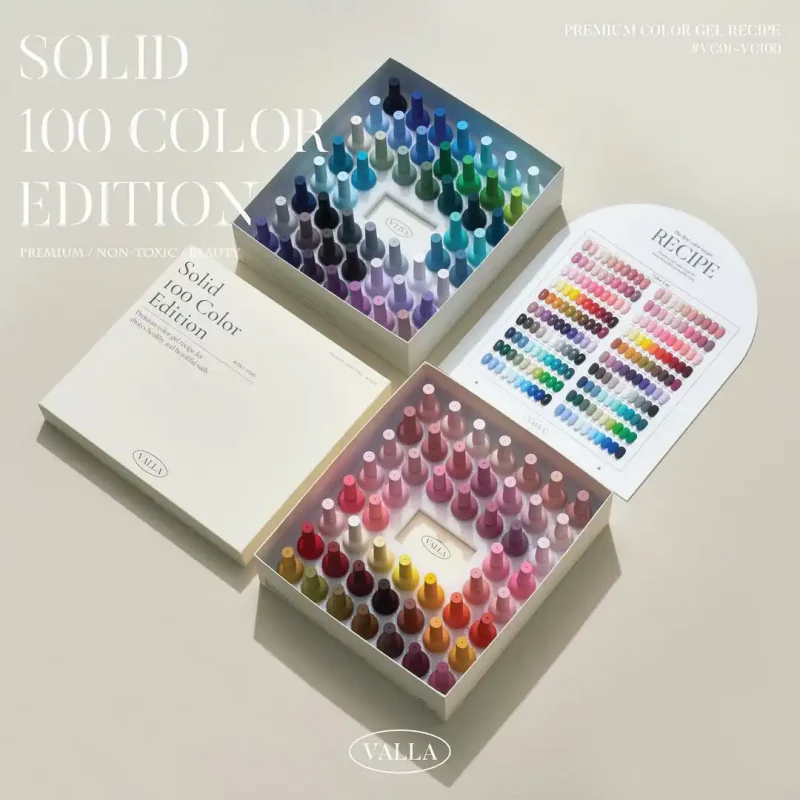

Colour Range, Effects, and Finish

Korean gels are known for high pigment density and smooth self-levelling, enabling uniform coverage in thin coats.

A wide spectrum of effects—jelly translucents, cat-eye magnetics, velvets, glassy toppers, fine glitters—are formulated to cure within standard exposure windows when applied as directed.

Effect gels may contain reflective or magnetic particles; maintaining thin layers preserves cure depth and optical clarity.

Regulatory and Technical Background (EU)

In the European Union, gel nail products are cosmetic products under Regulation (EC) No 1223/2009.

Compliance includes an EU-based Responsible Person, a Product Information File with Cosmetic Product Safety Report, INCI labelling, and CPNP notification. Annex restrictions apply to certain monomers and photoinitiators.

For a neutral chemistry-oriented explainer you can reference your in-site resource:

Chemistry and ingredients of nail gels.

Common Misconceptions (Quick Clarifications)

- “Thicker coats last longer.” False. Thin, fully cured layers provide better cross-linking and durability.

- “Peeling off gel is harmless.” False. Peeling can remove superficial nail layers and weaken the plate.

- “Allergies only happen to clients.” False. Repeated occupational exposure makes technicians equally (or more) at risk without proper controls.

Summary

Korean gel nail systems are UV/LED-cured coatings optimized for smooth application, high gloss, and extended wear.

Their formulation philosophy emphasizes efficient self-levelling, modern “free-from” profiles, and structured techniques that support nail health when applied correctly.

Performance depends on rigorous prep, thin layers, matched lamp curing, and careful avoidance of skin contact.

For additional technical context and chemistry details, see

gel-polish curing basics

and your in-depth explainer

chemistry and ingredients of nail gels.